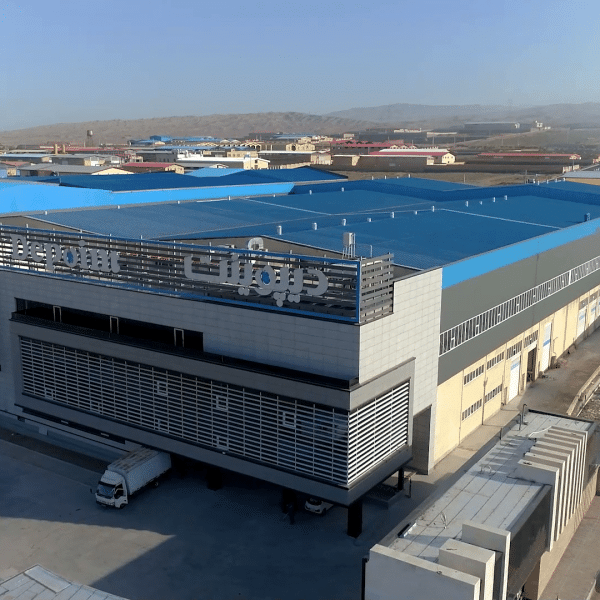

Design and Construction of the Depoint Refrigerator Factory

Depoint, a subsidiary of Gol Asay Sarma, is a knowledge-based company specializing in refrigerator production. Geographically, the project site is located in the Ivankay Industrial Town of Semnan Province. The Arian Mahdekavosh team has provided all design and construction services for the Dipoint refrigerator factory, including engineering, procurement, and execution. The project saw the construction of two types of two-story industrial sheds, each measuring 105 by 30 meters in length. Ground floor of these sheds serves as a warehouse, while the second floor houses the factory’s production line. Additionally, a four-story administrative and exhibition building for the Depoint factory was designed and executed on a 2000 square meter site within this project. The esteemed employer, Mr. Engineer Mansouri, worked in complete coordination with the Arian Mahdekavosh engineering company. Thanks to his worthy collaboration and support in the design and execution of the project, all aspects of the factory’s construction were successfully completed.

Necessary Permits for the Design of the Depoint Refrigerator Factory

For the Depoint factory project, the initial construction permit was obtained from the Semnan Industrial Towns Company. The factory was built on a total land area of 30,000 square meters. Initially, an area of 15,000 square meters was allocated, but in the second phase, an additional 5,000 square meters was added, totaling 20,000 square meters for the Depoint factory’s construction.

Land Specifications of the Factory

The land for the Depoint factory had a general north-to-south slope with a 12-meter elevation difference. According to the architectural plan provided, 6 meters of this elevation difference was leveled, reducing the height difference across the land to six meters and significantly saving on earth-filling and excavation costs. The administrative buildings, production hall, and warehouses were linearly designed by the Arian MahdeKavosh architectural studio in such a way as to considerably conceal the land’s slope. This approach resulted in a visually appealing and orderly view.

Design of the Depoint Factory’s Spatial Diagram

The sales department of the factory is located on the ground floor and the first floor was designed for an open office, with a Knauf and glass system implemented in the interior space. The product loading area in this factory was placed at the closest point to the factory entrance to minimize truck movement within the factory site. On the fifth floor of the Depoint factory’s administrative building, a roof garden was established, and on the fourth floor, a meeting hall was set up. The roof garden area was designed as a lounge for waiting before meetings commence in the meeting hall.

Stages of Factory Construction

Structural Specifications

In this project, four types of industrial sheds for the production line and storage, covering an area of 16,000 square meters with spans of 36 and 16 meters across two floors, were designed and executed. The structural system of the sheds consists of ordinary ductility moment-resisting frames in the transverse direction and both divergent and convergent braced frames in the longitudinal direction. Administrative and exhibition building of the Depoint factory was designed and executed over four floors with a total area of 4,000 square meters. The structural system of the administrative and exhibition building is designed with intermediate ductility moment-resisting frames in both directions and a steel deck roofing system. In designing the structure of the Depoint factory, all principles and rules were applied in accordance with national regulations and up-to-date global standards.

Factory Facade Design

For the design and execution of the factory facade, dry porcelain ceramics and solar panels were used. Other materials employed include porcelain ceramics and glass, curtain wall face cap, cement board, and composite. If you wish to learn more about the materials used in this project, please refer to the articles below.

Facade photo album

Architectural Design Goals of the Depoint Factory

At the esteemed employer’s request, the design style of this project was executed in a modern and contemporary fashion. Special attention was paid to the construction process, capacity increase, and production speed for the design of the second phase of the Depoint factory. The design and construction of the factory were presented in such a way as to consider the future expansion of the facility. Depoint factory places special emphasis on the principle of using sustainable energy and reducing electricity consumption in its refrigerator production.

At Arian MahdeKavosh, we endeavored to pay special attention to this principle in our factory design. Therefore, this was demonstrated by installing solar panels on the facade of the administrative building. The administrative building and the sheds were designed continuously so that the factory head could have a comprehensive view of the entire production hall. To better display the spaces used in the design of this project, a model was created for the Depoint factory as shown below.

Building the Depoint Factory Model

Design of the Administrative Building’s Facade

After the completion of the shed structure and its framework, the facade of the administrative building was executed using dry ceramics and cement board. This facade system requires no secondary actions and was directly applied to the raw framework. The administrative section was designed as a box, and its facade was constructed using dry ceramics, sandwich panels, and bricks.

Interior Design of the Administrative Building

Within the administrative complex of the factory, there is a lobby with a three-story height. The design of this area includes a suspended bridge that connects the eastern and western administrative sections. Behind the suspended bridge, a three-meter-high billboard was designed and executed for advertising purposes and displaying Depoint factory products. The walls of the management room were designed and executed with electrically opaque glass.

Design of the Factory Exhibition Building

Lighting Design of the Administrative Building’s Facade

The lighting of the administrative building’s facade was specially designed and is distinctly visible from a distance. This design created unique advertising opportunities for the Depoint factory. In the architectural design of this factory, along with the design of the building and sheds, advertising opportunities and strategies were also considered.