Design and Implementation of Aseh Tejarat Asia Coil Factory

The production line of Aseh Tejarat Asia’s industries is actively engaged in cooling and heating solutions, exporting all its products internationally. Geographically, the factory is located in Tehran Province, in the Sharifabad district after Pakdasht, within the Khwarazmi Industrial Town. The Aseh Tejarat Asia complex comprises three distinct sections: a door manufacturing plant, a condensing unit factory, and a coil factory. This article will provide details about the coil factory. It should be noted that all executive operations and redesign of the Aseh Tejarat Asia complex were carried out by the Arian MahdeKavosh engineering consultancy team. For more examples of our work in the design and construction of factories and industrial sheds, please visit the “Industrial Factories and Sheds Projects” page.

Aseh Tejarat Asia Coil Factory Site Specifications

The coil factory of Aseh Tejarat Asia is the largest in this collection of refrigeration industry factories. The land area of this factory is 22,000 square meters, located on Narges Street geographically. Previously, there was a factory on this site, which was demolished at the beginning of the project, and a new factory was designed and constructed from scratch. The layout of the coil factory includes 9 sheds. Of these 9 sheds, four are related to the production line, one serves as the engine room and facilities for the sheds, and the rest are used as warehouses. The first shed is similar to the condensing unit factory and has a mezzanine. The administrative section of this complex is located on the mezzanine, albeit with less office space than the door manufacturing factory located on Laleh Street.

Coil Factory Applications

This factory has three main entrances, two of which are on Narges Street; one entrance is specifically for warehouses, and the other is for the production line. The main machines of Aseh Tejarat Asia are located in this factory. These machines include punch, laser, and Steven welding machines for the coils themselves, used for welding copper pipes. All fan coils and ventilation devices are produced in this factory, and tests and experiments are conducted. In the next stage, they are sent to the condensing unit factory.

The entrance gate and the entrance and security rooms of this factory were also designed and implemented by Arian MahdeKavosh Architectural Studio. Electrical rooms for all three factories were designed and implemented. In the design and construction of the factory’s perimeter wall, ACC blocks (Hebel) were used. The interior part of the factory’s grounds was made with washed cement.

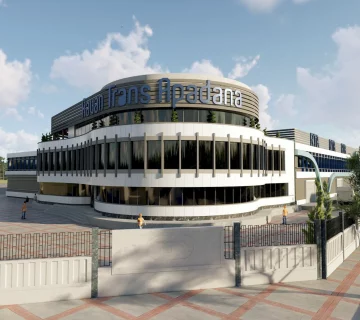

Facade Design Concept

The facade design of this factory is inspired by repeating rhythms. The roofs of the factory sheds have been executed in an up-and-down fashion instead of the usual octagonal shape, aiming to create an entryway for natural light. In the design, dark colors were used at the employer’s request.

Execution of the Coil Factory Facade

In the execution of the factory’s facade, dry ceramics were used with the keel and curtain wall method. The floor covering of all sheds is made with self-leveling concrete (Armalat in Persian). For the roof covering of the sheds, sandwich panels were used instead of the commonly used Iranianit (Asbestos cement) in other factories. The administrative parts of the factory are entirely glass facades, and the internal partitions are all glass, providing a complete view of the surroundings and landscapes of the factory and inside the administrative building.

No comments yet