Design and construction of Simco Polymer factory

The Simco Polymer factory design and construction project which is located in the industrial town of shahriyar or Qasem Soleimani in Tehran began in 2019. Simco polymer is a subsidiary of Simco and operates as a manufacturer of polymer products such as wires and cables. land area of the project is 36,000 square meters, of which 14,400 square meters were built in the first step of construction. The remaining 21,600 square meters of space was also designed for future factory developments and is expected to begin its implementation soon. The design and implementation of the facade, the interior architecture of buildings, warehouses of raw materials, production sheds and all service buildings and the reconstruction of the office building of simcopolymer was carried out by Arian Mahdekavosh consultanting engineers. For more portfolios on the design and construction of factories, see the page “portfolio”.

Article index:

Factory site features

Most industrial town are located in areas where there is no vegetation. The site of the Simco Polymer Plant is located in the polymer zone of the industrial town of shahriyar. The site terrain of the project has a unfortunate condition in which it has a rocky substrate and very loose soil. To make reinforce soil, this collection of loose soils was collected and then pedestal was implemented. The rocky substrate prevents vegetation from growing and also is used to direct surface water flow. As a result, a pool was designed in the southern part of the site. this pool was designed to collect and store surface water and use it to irrigate the green space of the plant and the site complex. Due to the looseness of the soil, a series of routes of communication channels were implemented. The final flooring cover of the concrete was laid.

Design and construction of wire and cable factory

In the construction of the project, seven industrial shed and a central office building were built. including five production shed and two other industrial shed were designed and implemented as a warehouse of raw materials and products. About 40 percent of the site’s land was also intended for future development. various sections have been meticulously planned to serve distinct functions within the premises of the Simco Polymer factory. These designated areas encompass raw material and product production warehouses, facility building, central administrative building, factory headquarters, laboratory and sampling sections, and guard and post building, in addition to essential electrical installations and related components. also, in the design of this factory, a main square was considered for installing the factory flag and its central advertising.

The physical layout of the plant

Efficiency in space utilization and seamless movement across various departments stand out as crucial aspects in factory design. A key professional tenet and distinguishing factor of our offerings at Arian Mahdekavosh, in comparison to our peers, is our meticulous analysis of spatial placement to maximize productivity. At Arian Mahdekavosh, we conduct preliminary consultations on production processes prior to commencing architectural design. These recommendations are geared towards enhancing connectivity between components pertaining to product manufacturing, storage facilities, trolley truck routes, scales, and secure controlled areas.

Through the creation of diagrams and spatial configurations, along with the presentation of multiple proposals to the client, we aim to enhance industrial engineering processes and production efficiency. Factors considered include spatial layout, manpower hours, forklift pathways, optimal warehouse-to-production distances, and the necessary space for trolley truck maneuverability and access points, among others.

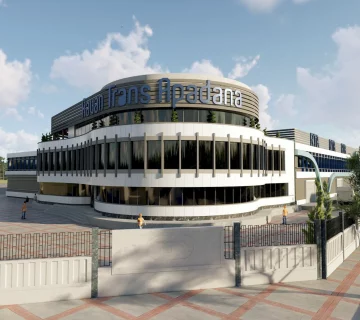

Space diagram of the central building and the factory office

The administrative building of this complex is centrally located and features the construction of a sampling hall and a laboratory as important components. In the sampling hall and laboratory section of this factory, a crucial area called the clean room has been designed for conducting experiments and data collection. On the ground floor of this central building, a restaurant has been incorporated, housing a kitchen, reception hall, and dining area. Prior to entering the main hall, restrooms and lockers are conveniently situated on the ground floor. Right in the central part of the building, an Iranian-style portico has been designed. The eastern side of the building houses the main administrative offices.

On the second floor of this central building, above the laboratory and sampling hall, units for research and development (R&D) and quality control (QC) have been established. Additionally, on the second floor of the central building, a cafeteria has been provided for administrative staff.

Within a section of the main factory building, a complete suite has been designed and executed for accommodating and hosting foreign guests. This suite includes a bedroom, bathroom, and restroom. On this floor of the central factory complex, management offices and department heads’ offices are located. These floors have access to the highest level via a spiral staircase and an elevator. The external facade design of the third floor is hexagonal. Positioned at the highest point of the factory site, this floor provides a complete overview of the entire factory site, including production halls, warehouses, loading and unloading areas, and more. On this floor, two separate halls have been designated for meetings and gatherings, along with the overall factory management office. Access from this floor to the reception and dining halls is facilitated by a glass tunnel.

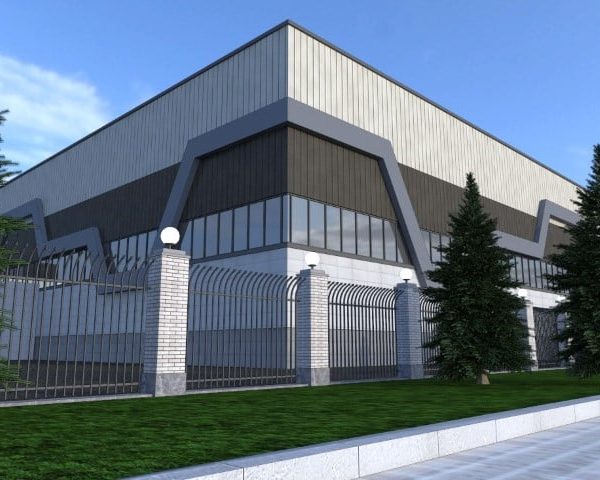

Design and implementation of Simco polymer factory facade

The facade design of warehouses and production sheds of the Simco Polymer factory used industrial colors black, white and gray. Dry ceramic and aluminum composite were used to cover the walls of these industrial sheds. long horizontal windows and sandwich panels in the form of vertical walls were used in this project. The industrial sheds were designed and executed in the form of a box.

The concept of this design is inspired by the molecular bonding of carbon in the form of a hexagon. This is quite clear in the design of the production office and the management department building. The most important part of the design of Simco Polymer factory is the use of a cubic form and avoidance of common and old forms which is the famous repeating triangular shape in the side face for a industrial sheds. Design of the factory walls also used a frame-less curtain Wall. The outer fences of the factory premises were also exclusively designed.

In the design of factory pattern diagram template, a special route for the entry and exit of the trolley truck was defined, which is the shortest and most optimal route for the movement of the trolley trucks. The design of this route saves considerable time and factory costs.

Simco polymer factory portal design

To enhance the integrity of the factory facade with the main entrance, a hexagonal design was used. Given that Simco Polymer’s factory activities are related to wire and cable coating production and other chemistry-related processes, we have aimed to incorporate chemical bonds into the factory’s design. It worth to mention that various alternative designs for the entrance of this facility have been presented, and you can view them in the accompanying images.

For consultation regarding design, implementation, and construction of factories, warehouses, or industrial units, you can contact our experts at the company’s phone numbers listed at the bottom of this page.

No comment