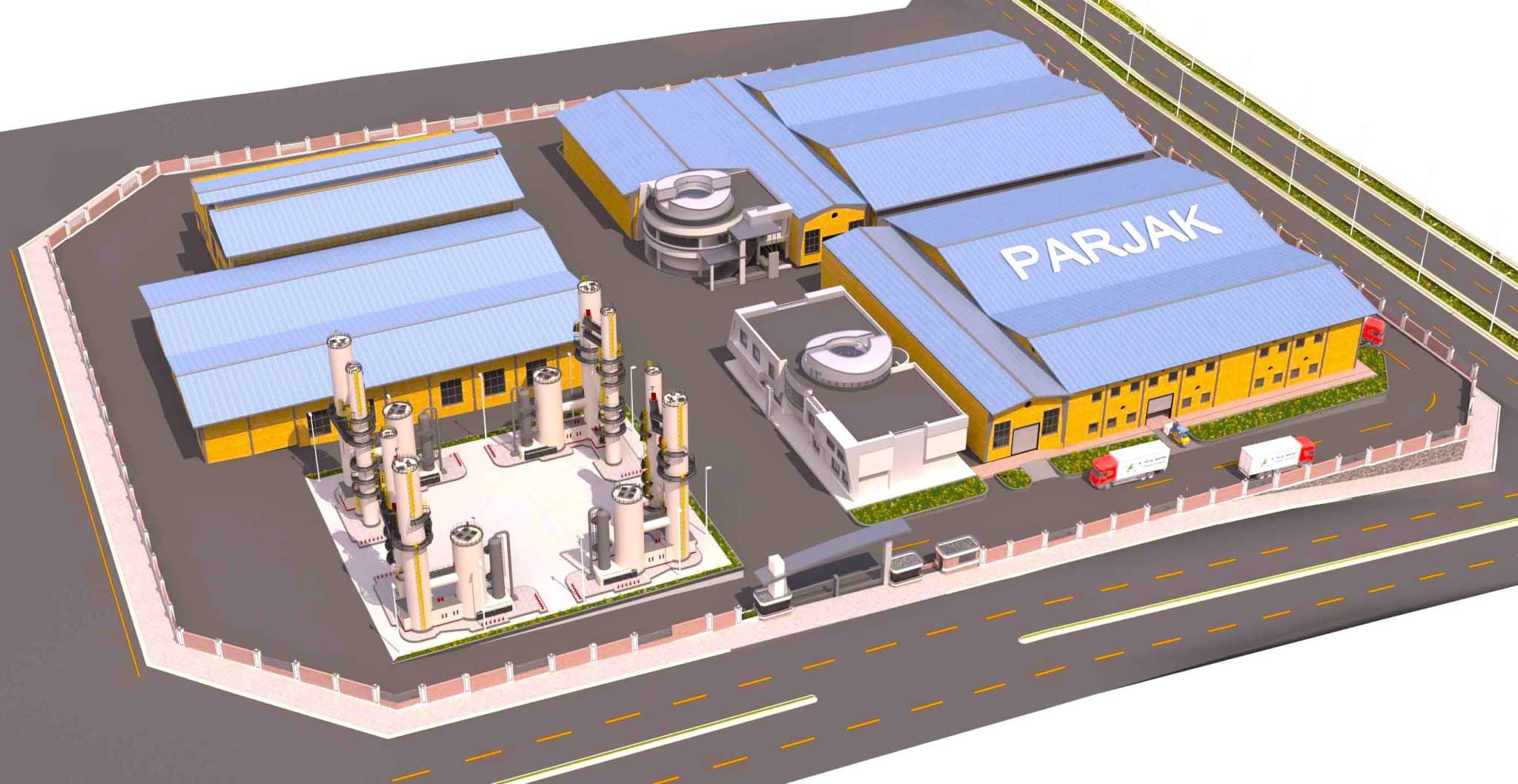

Design and Construction of the Parjak Factory

The design and construction project of the Parjak Factory, located in the Ivankay Industrial Town, commenced in the year 2014. Arian Shokoufa Health Company, trading as Parjak, operates as a manufacturer of cosmetic and hygiene products, particularly specializing in shampoos. The site for this project spans an area of 20,000 square meters. Out of this area, 9,600 square meters are dedicated to production halls and warehouses, and 1,800 square meters are allocated for the administrative building and the factory’s staff facilities. The facade design and execution of the factory, the interior architecture of the administrative building, and the design and supervision of the construction of the production halls and raw materials, as well as all the service buildings of the complex, have been carried out by Arian Mahdkavosh Engineering Consultants. For more examples of work in the field of factory and industrial hall design and construction, please visit the “Industrial Factories and Halls Portfolio” page.

Factory Site Specifications

In many industrial towns, the existing soils are of the manual type, and to achieve a suitable and firm foundation for factory construction, some areas need to be compacted, excavated, or the foundation site reinforced. For large-scale lands intended for factory construction, leveling, excavation, and embankment are among the costly items of any project. If the different sections of the factory are not properly located and the existing topography is not utilized correctly, excessive costs will be imposed on the project.

Structural System and Architecture

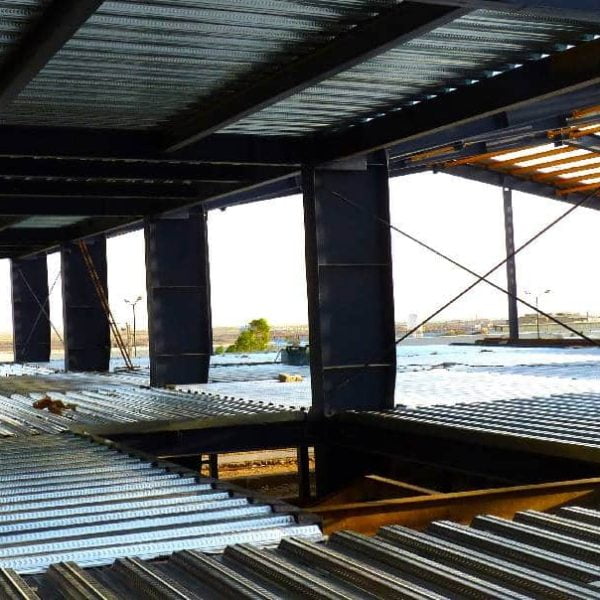

The industrial complex of the Parjak production factory includes 4 production and storage halls with spans of 30 and 20 meters, an administrative management building, and a staff building. This factory is located in the Ivankay Industrial Town in Semnan Province. The production hall of the Parjak factory was constructed on a land area of approximately 9,600 square meters. The factory halls are designed as storage for production and products. The halls have a mezzanine with a heavy structural roof of the steel deck type. The structural system of the administrative and staff buildings of Parjak is a steel moment frame in one direction and a braced frame in the other, with a steel deck roof.

Design of the Shokoofa Behdasht Aryan (Parjak)

One of the design features of this project is the use of the site’s topography and current conditions for the placement of the halls and the factory’s loading dock. Therefore, some of the factory halls of Parjak were designed as two-story. In the two-story halls, the middle wall of one of the halls was constructed in a stepped manner and at a higher elevation than the other to allow natural light to enter the halls. This measure led to reduced energy consumption and optimal use of natural light in the production halls.

The foundation strengthening and location of the different sections of this project were carried out based on the efficiency and the employer’s requirements. In the factory design, the arrangement of different parts can vary depending on the industrial unit’s function and the employer’s needs. For example, the arrangement of a factory’s sections can be linear, circular, puzzle-like, etc. When placing the factory buildings, the following points should be specially considered:

- Efficiency and activity of the project

- Issues and regulations of industrial towns, such as firefighting

- Traffic of the factory’s freight vehicles

- Climatic conditions (windiness of the region, topography of the land, etc.)

Considering the points mentioned above, we presented various building placement designs in this project, which ultimately, after several iterations, the linear arrangement was approved by the employer.

Spatial Diagram of the Parjak Factory

In the northern and eastern parts of the factory, the raw material and shampoo production warehouses are located. In the central part of the site, an administrative building has been designed, whose ground floor includes a laboratory, quality control department, and cleanroom. The open office space, guest suites, and management room are located on the upper floor. The service area and the workers’ staff building were constructed separately from the administrative building at the request of the esteemed employer. The staff building of this complex was designed in the shape of a circle, including a dining area, restrooms, a prayer room, and workers’ changing rooms. The production hall and product storage halls were also located in the southern part of the site. At the southernmost part of the factory site, a loading dock was designed and then constructed for unloading and loading raw materials and factory products.

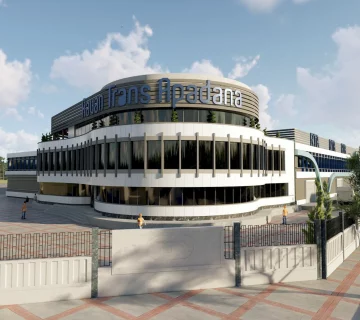

Administrative Building of the Parjak Factory

The administrative building of the Parjak factory was constructed on a land area of 1,800 square meters. The esteemed project employer wished for the entrance lobby of the administrative building to be designed in such a way that natural light would enter through a glass roof. Considering the taste and idea of the esteemed employer in the interior design of the complex, a glass roof was placed in the middle of the lobby as a central atrium. A tall and inviting entrance in the center of the building divides the space and is very eye-catching. The design of this part was inspired by a cylindrical form. The connection between the floors of this building was also established by a spiral staircase.

Exterior View and Grounds of the Factory

Some factories store a part of their raw materials or produced goods in the factory site and grounds. In the design of the Parjak factory, the inclusion of such a space was requested to use this part of the grounds for the placement of raw material tanks. Also, a plaza space for gatherings and a roof garden in the form of a semi-circular roof, along with green space and landscaping of the Parjak factory, were designed. This section was not implemented during the construction of the factory but was considered for future development. It is worth mentioning that the materials used for the facade of the administrative building of the Parjak factory are brick and partly sandwich panels.

Loading Dock of the Parjak Factory

The loading dock of the factory was located near the factory’s exit gate to minimize the need for truck traffic within the complex. In the loading dock area, a series of loading platforms with 45-45 degree angles were installed, where trucks are positioned obliquely, and the trucks’ cargo is directly entered into the halls from the same elevation level. The structure of the factory’s loading dock was constructed with a truss system using tubular profiles. Since the Ivankay Industrial Town in Semnan Province is a very windy area, the loading docks of the Parjak shampoo and cosmetic hygiene products factory were designed to allow the wind to pass through them.

The loading dock of this project was covered to protect the truck cargo and facilitate the workers’ activities in cold, hot, windy, and rainy weather. Since it was necessary for the loading dock to be covered, we faced limitations in presenting different details. Considering the windiness of the region, sinusoidal movements were used in the design of the loading dock roof. Also, the roofs of the loading docks were designed in a stepped manner to facilitate wind movement and prevent the roof from being thrown off and damaged.

Design of the Parjak Factory Wall and Entrance

The esteemed employer’s request for the design of the factory’s exterior walls was to use a brick base, which our design engineers designed the factory wall according to their wishes. Since the cost of constructing factory walls is a significant amount, in this project, we tried to present a design that was neither too simple to lack a special appearance nor too elaborate to increase construction costs. The employer’s request was implemented in the best way possible, and savings were made in the costs. The Parjak factory’s guard unit was designed as a two-story building. The design of the entrance gate of this factory was also carried out by Arian Mahdkavosh Architecture Studio.

No comments yet